Rubber goods are processed by machines called rubber extruders. Extrusion is the process of heating, pressing, cooling, and forcing raw material through a die to shape it into a new shape. First, tools called dies are created specifically to mold raw materials into new shapes. After that, the substance is thoroughly cooled and hardened. Read More…

Aero Rubber Co. offers exceptional quality and competitive pricing on all of our extruded rubber products. Aero Rubber Co. uses high quality rubber compounds such as, Neoprene, Viton, Silicone, EPDM, Polyurethane, Natural Rubber, and Thermoplastic Rubber.

At Kent Rubber Supply Co., we specialize in providing high-quality rubber tubing solutions to meet the diverse needs of our customers. With decades of experience in the industry, we take pride in offering a comprehensive selection of durable, reliable, and customizable rubber tubing products. Our tubing is designed to perform in a wide range of applications, including industrial, commercial, and...

National Rubber values quality, consistency, and fast delivery of our products. Our components are made from a variety of elastomers such as neoprene and silicone, and our team members are capable of turning your drawing into the part you need. Contact us today to tell us about your next project!

GSH Industries supplies rubber extrusions to a range of industries. We offer rubber in materials such as Neoprene, Viton®, Nitrile, Silicone & more. We have tooling ability to create intricate profiles ensuring rubber goods are of the highest quality.

More Rubber Extruder Manufacturers

Understanding the Rubber Extrusion Process

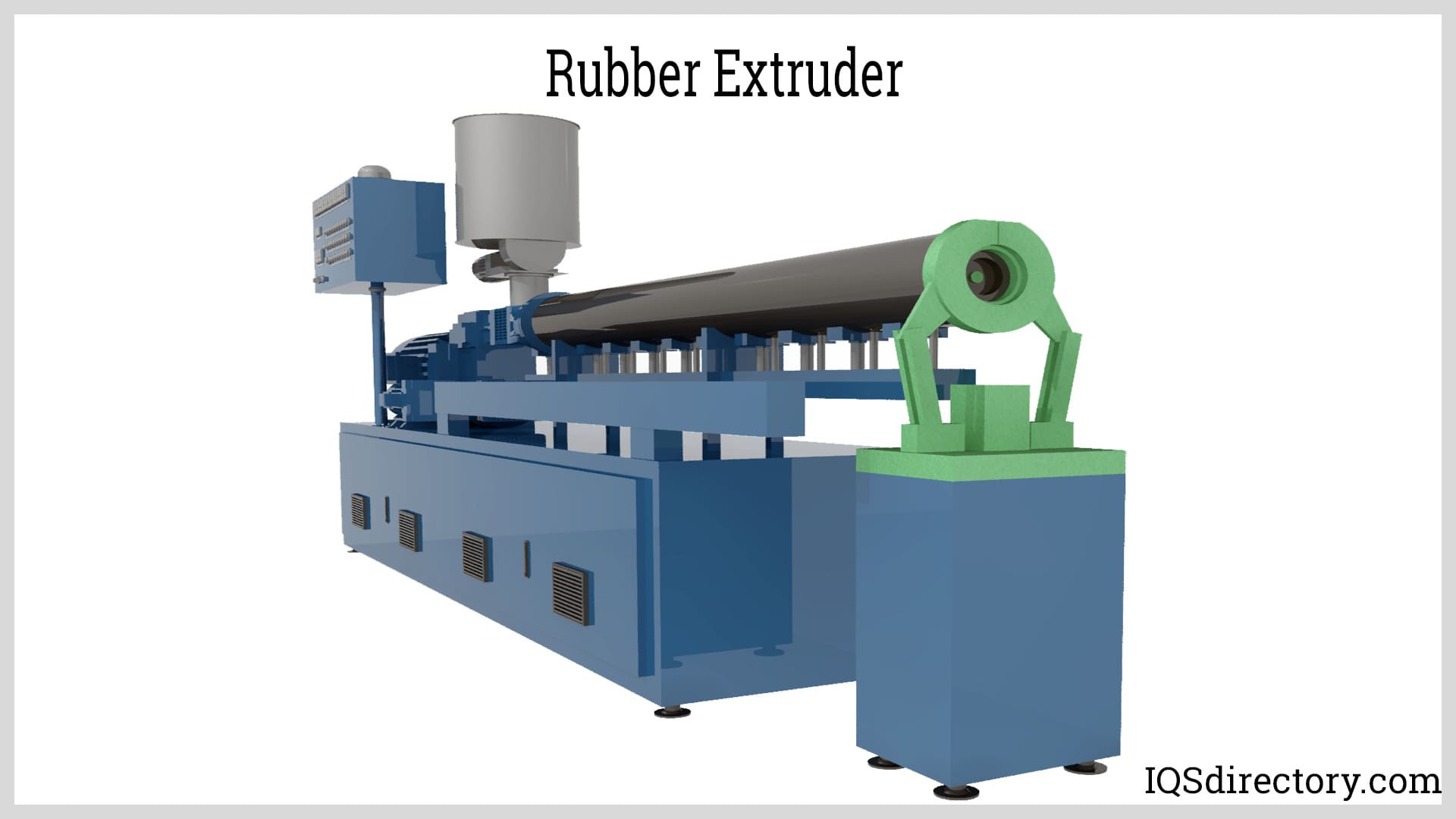

The rubber extrusion process is a critical manufacturing technique used to produce a wide variety of custom rubber profiles, seals, tubing, and industrial components. In this process, a carefully formulated rubber compound is introduced into a high-precision rubber extruder machine. The material is fed through a hopper, which transfers it into the rotating screw’s flutes inside the barrel. As the screw turns, it pushes the rubber forward, increasing both temperature and pressure as the material approaches the die.

The rising pressure forces the malleable rubber through the die's apertures, which are shaped to match the desired cross-sectional profile. As the rubber exits the die, it may expand or contract depending on its compound formulation and hardness. This tendency for dimensional change is known as die swell, and it requires precise engineering to maintain tight tolerances for finished extruded rubber products. Vulcanization, or curing, is then performed on the extrudate to set its final shape and physical properties. During this stage, the rubber may further shrink or alter in length, often more in the center than at the ends.

Are you curious about how specific rubber extrusion techniques impact the durability and flexibility of finished products? Explore common applications and industries below.

Versatile Applications for Rubber Extruders

Rubber extruders are engineered to work with both natural rubber and synthetic rubber compounds, enabling the production of an extensive range of industrial and commercial products. The ability to process materials such as EPDM, silicone, nitrile, Neoprene, and Viton allows manufacturers to address varied application requirements, from automotive weatherstripping to high-performance chemical seals.

Some of the most common rubber extrusion applications include:

- Weatherstripping: Used in automotive, construction, marine, and aerospace industries to create seals that guard against water, dust, and air infiltration.

- Trim and Edge Protection: Applied to panels, doors, windows, and hatches to prevent damage, reduce noise, and seal gaps.

- Grommets and Bushings: Serve as vibration dampeners and electrical insulators in machinery, vehicles, and consumer products.

- Bumpers and Impact Protection: Essential in loading docks, marine environments, and industrial safety systems for shock absorption and equipment longevity.

- Tubing and Hoses: Widely used in hydraulic, pneumatic, medical, food-grade, and chemical transfer systems.

- Custom Profiles: Designed for OEM (original equipment manufacturer) needs in mining, railroad, agriculture, appliance manufacturing, and more.

Different industries and end-use environments require unique rubber extruder configurations—from basic single-screw extruders to complex co-extrusion lines and dual-durometer systems. For instance, a manufacturer serving the HVAC sector will specify different extrusion tooling and material blends than one producing automotive door seals or medical-grade tubing.

Looking for industry-specific rubber extrusion solutions? View custom rubber seal options for your sector.

Key Products Made Using Rubber Extruders

The design flexibility and material versatility of rubber extrusion manufacturing yield an array of products tailored for real-world performance. Below are some of the most popular and high-demand extruded rubber items:

-

Rubber Bushings:

Extruded rubber bushings are essential shock absorbers and vibration isolators used in moving machinery. They help separate moving parts, minimizing noise and mechanical wear. Most commonly found in automotive suspension systems, engines, and heavy equipment, these bushings are typically hollow cylinders—an ideal shape for extrusion. They can be used as standalone components or further processed with metal casings for enhanced durability and load-bearing capability. For buyers evaluating rubber bushing manufacturers, consider application-specific requirements such as hardness, oil resistance, and temperature tolerance.

-

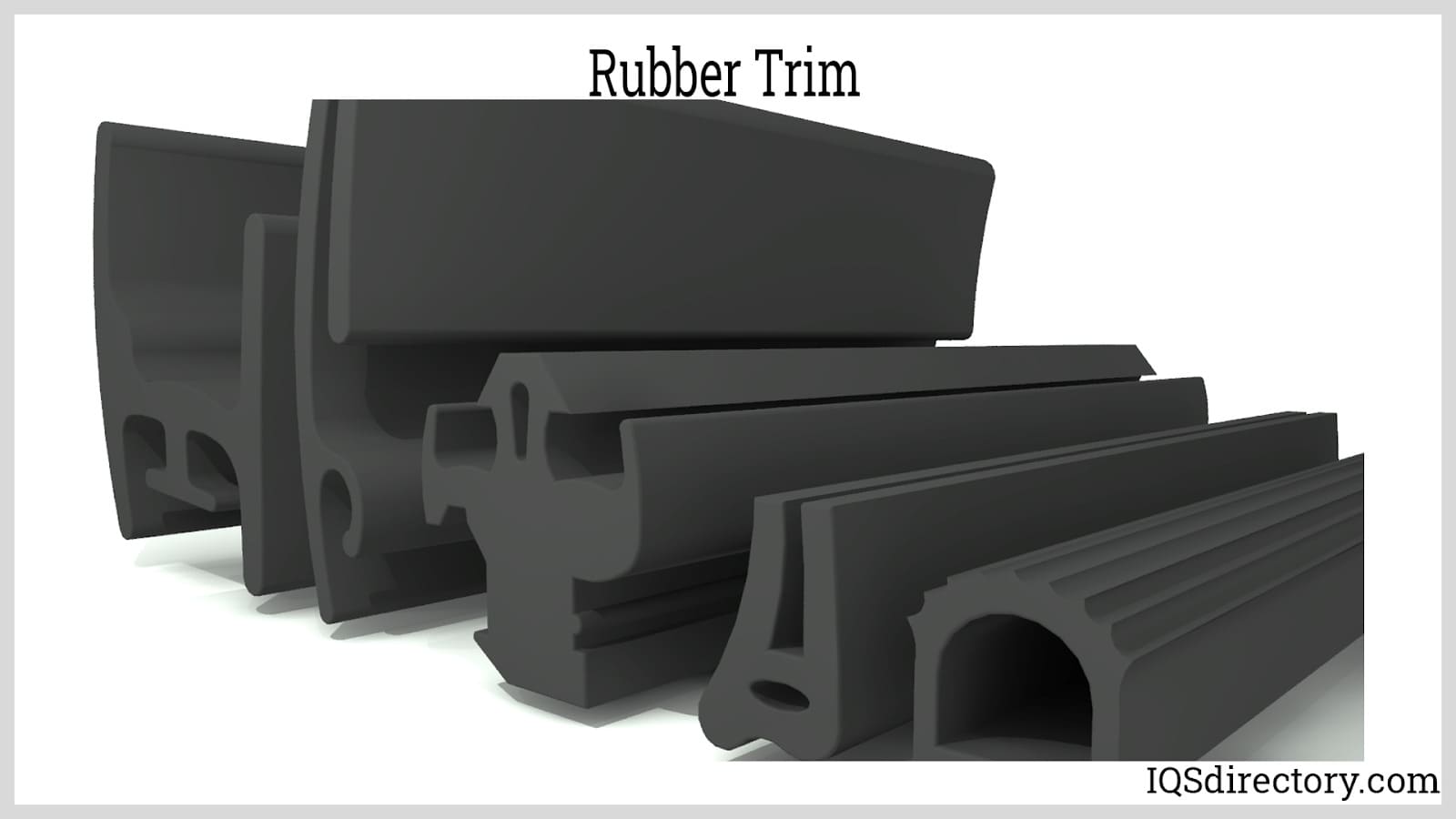

Rubber Trims:

Extruded rubber trim is engineered to cushion and seal the edges of panels, windows, doors, and hatches. Rubber trims not only provide impact resistance but also offer superior weather sealing, preventing air and water leaks in both stationary and mobile applications. U-channel trims, bulb seals, and edge protectors are widely used in automotive, marine, and industrial settings. Many trims are custom-profiled for OEM applications, utilizing fasteners or adhesives for secure installation. When specifying rubber trim profiles, buyers should consider UV resistance, color matching, and compliance with industry standards.

-

Rubber Bumpers:

Rubber bumpers harness the material's natural shock-absorbing and abrasion-resistant properties. They are widely used in logistics (docks, loading bays), marine (boat and dock fenders), and road safety applications. D-shaped and cylindrical cross-sections are popular, with the flat side mounted to a structure while the rounded side absorbs impact and protects equipment. When sourcing extruded rubber bumpers, assess factors such as hardness, resilience, and compatibility with mounting hardware.

-

Additional Products:

The extrusion of rubber tubes, hoses, and pipes supports critical applications in fluid transfer, pneumatic systems, and chemical processing. Food and pharmaceutical industries demand FDA-approved rubber extrusions with cleanability and bio-compatibility. In industrial automation, rubber extrusions are used for cable management, protective coverings, and insulation. The inherent flexibility and customizability of extruded rubber make it the material of choice for joining machinery, transporting compressed air, oil, water, and chemicals, and creating specialty gaskets and seals.

Custom Rubber Extrusion Capabilities and Advanced Manufacturing

Today’s rubber extrusion manufacturers invest in advanced technology to produce high-precision, custom rubber profiles and extruded components. Computer-aided design (CAD), 3D printing for die prototyping, and automated quality control systems enable rapid prototyping and consistent production quality. Many suppliers offer value-added services such as:

- Co-extrusion: Combining two or more rubber compounds to create dual-durometer or multi-material parts with enhanced performance.

- In-line splicing and joining: For continuous gaskets and large frame assemblies.

- Color matching and striping: To meet branding or safety requirements.

- Fabric or wire reinforcement: For hoses and seals requiring additional strength.

Need a custom rubber extrusion for your application? Request custom quotes from leading manufacturers.

Finishing and Secondary Processes for Rubber Extrusions

After extrusion and vulcanization, many rubber products undergo finishing processes to achieve precise dimensions, add features, or prepare for final assembly. Common finishing options include:

Punching

Punching introduces holes or slots into extruded products, such as hatch seals, bumpers, and fenders. This secondary operation is vital for alignment, venting, and attachment points in the finished part.

Cutting

Post-vulcanization cutting ensures extrusions meet exact length requirements. Offline cutting enables angled or mitered ends with tight tolerances. Automated fly cutters and guillotines can process large production runs efficiently and with high repeatability.

Printing

Inline printing adds traceability and identification to rubber extrusions. Manufacturers can mark parts with lot numbers, batch codes, contact information, regulatory data, or barcodes for supply chain management and quality assurance.

Drilling

Drilling is employed when thicker or harder extrusions require holes or slots that punching cannot achieve. This process is common for durable, reinforced rubber parts used in heavy-duty applications.

Forming the Corners

By molding or bonding extruded profiles together, manufacturers can create complex frames, corner joints, and continuous seals for windows, doors, and large enclosures. This approach enhances design flexibility for custom assemblies.

Riveting and Welding

Welding and riveting attach extruded rubber parts to other materials or components—useful for products like flexible ladders, modular bumpers, and composite assemblies. Advanced bonding techniques improve joint integrity and long-term durability.

How to Choose the Best Rubber Extruder Manufacturer

Selecting the right rubber extruder manufacturer is critical for ensuring consistent quality, reliable supply, and optimal product performance. With a wide range of rubber extrusion suppliers available, buyers should consider factors such as technical capability, material expertise, lead times, and value-added services.

- Experience and Industry Knowledge: Look for manufacturers with a proven track record in your application sector (automotive, HVAC, medical, marine, etc.).

- Material Selection: Leading suppliers offer a variety of compounds—EPDM, silicone, neoprene, nitrile, Viton—and can recommend the best formulation for your needs.

- Design Support and Prototyping: Evaluate manufacturers that provide CAD assistance, rapid prototyping, and tooling customization to accelerate product development.

- Quality Assurance: ISO certification, in-process inspection, and documented testing protocols ensure consistent product performance and regulatory compliance.

- Production Scalability: Choose a partner with capacity for both low- and high-volume production, as well as flexibility for custom orders.

- Secondary Operations: Seek suppliers offering cutting, punching, splicing, adhesive application, and assembly for streamlined procurement.

- Customer Service and Communication: Responsive support, transparent lead times, and clear quoting processes simplify collaboration and project management.

How can you compare top rubber extruder manufacturers? Use our comprehensive rubber extruder directory to review business profiles, capabilities, and certifications. Each listing includes contact information and links to request quotes directly from suppliers, streamlining your vendor selection and procurement process.

For optimal results, it’s recommended to compare at least four manufacturers. Visit each company’s profile and website using our patented website previewer, and leverage our RFQ (Request For Quote) form to reach out to multiple suppliers with a single submission. This approach maximizes your ability to secure competitive pricing, technical expertise, and product quality tailored to your project requirements.

Benefits of the Rubber Extrusion Process

Why choose rubber extrusion for your next project? The extrusion process offers several advantages over alternative manufacturing methods, including:

- Design Flexibility: Enables the creation of intricate, continuous profiles in virtually any cross-sectional shape, from simple tubes to complex multi-chambered seals.

- Material Versatility: Accommodates a wide range of polymers and custom rubber blends to deliver the required properties—chemical resistance, weatherability, flame retardance, or food-grade compliance.

- Cost-Effectiveness: Supports high-volume production with minimal material waste, reduced tooling costs, and efficient changeovers.

- Performance: Delivers products with excellent mechanical properties, durability, and consistent dimensional accuracy.

- Customization: Easily integrates color, texture, surface finishes, and secondary features such as adhesive backings or metal inserts.

Still have questions about the rubber extrusion process or the best materials for your application? Contact our technical experts for personalized guidance.

Frequently Asked Questions About Rubber Extrusion

What is the typical lead time for custom extruded rubber products?

Lead times vary by manufacturer, product complexity, and order volume. Standard products may ship in days, while custom profiles requiring new tooling or special compounds typically have a lead time of 2-6 weeks.

Which rubber compounds are best for outdoor and UV exposure?

EPDM and silicone rubber are top choices for weather resistance, UV stability, and temperature extremes. For chemical or oil resistance, consider nitrile or Viton compounds.

How do I determine the correct tolerance for my rubber extrusion?

Tolerances depend on material, profile geometry, and application requirements. Consult with your manufacturer to balance performance and manufacturability.

Can extruded rubber products be colored or branded?

Yes, most manufacturers offer color matching, striping, and even custom surface texturing or printing for branding and traceability.

What are the minimum order quantities for custom rubber extrusions?

Minimums depend on tooling costs, material selection, and supplier policy. Many manufacturers accommodate low-volume prototypes as well as large-scale production runs.

Take the Next Step: Source Your Rubber Extrusion Solution

Whether you’re seeking a custom extruded seal for a demanding industrial application, a weatherproof trim for automotive doors, or FDA-grade tubing for food processing equipment, the rubber extrusion process delivers unmatched versatility, durability, and value. By working with an experienced rubber extrusion manufacturer, you gain access to cutting-edge materials, design support, and precision manufacturing to meet your exact specifications.

Ready to get started? Compare leading rubber extruder manufacturers now or contact our team for expert advice, quotes, and material recommendations.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services