A rubber sheet consists of rubber molded into flat sheets of an equal thickness, commonly offered on a roll for handling convenience. Rubber sheets typically range in thickness from 0.02 to 1.6 in (0.5 to 40 mm). The use of the sheet is determined by its thickness and the type of rubber used. Read More…

Aero Rubber Co. offers exceptional quality and competitive pricing on all of our extruded rubber products. Aero Rubber Co. uses high quality rubber compounds such as, Neoprene, Viton, Silicone, EPDM, Polyurethane, Natural Rubber, and Thermoplastic Rubber.

At Kent Rubber Supply Co., we specialize in providing high-quality rubber tubing solutions to meet the diverse needs of our customers. With decades of experience in the industry, we take pride in offering a comprehensive selection of durable, reliable, and customizable rubber tubing products. Our tubing is designed to perform in a wide range of applications, including industrial, commercial, and...

National Rubber values quality, consistency, and fast delivery of our products. Our components are made from a variety of elastomers such as neoprene and silicone, and our team members are capable of turning your drawing into the part you need. Contact us today to tell us about your next project!

GSH Industries supplies rubber extrusions to a range of industries. We offer rubber in materials such as Neoprene, Viton®, Nitrile, Silicone & more. We have tooling ability to create intricate profiles ensuring rubber goods are of the highest quality.

More Rubber Sheet Manufacturers

Types of Rubber Sheets

Natural Rubber Sheet

The raw material for natural rubber sheets is latex, an emulsion derived from the bark of several plant species, containing between 60% and 80% water. A sheet of natural rubber can be compressed effectively, making it ideal for applications requiring flexibility and resilience. Natural rubber offers considerable resistance to non-mineral detergent acids and water, and it is recognized for its strong dynamic and rebound qualities. These sheets are highly resistant to tearing and deliver superior mechanical performance compared to many synthetic alternatives. Due to these properties, natural rubber sheets are widely used as anti-vibration pads in packaging, shock absorption, and gasketing. Common industries utilizing natural rubber sheeting include automotive, mining, and general manufacturing, where both durability and elasticity are critical.

Nitrile Rubber Sheet (NBR)

Nitrile rubber sheet, also known as NBR sheet, stands as the most popular and cost-effective elastomer in the seal and gasket industry. NBR rubber is renowned for its outstanding resistance to petroleum-based lubricants, fuels, water, alcohols, silicone greases, and hydraulic fluids. This makes it a top choice for applications in fuel handling, oil storage, automotive gaskets, and industrial hoses. Nitrile can withstand a broad temperature range, enduring both negative and positive temperatures from -58 °F to 255.2 °F (-50 to 124 °C). This versatility ensures its reliability in environments with fluctuating temperatures. NBR rubber sheets are characterized by a low compression set, strong abrasion resistance, and high tensile strength, making them suitable for seals, diaphragms, and other demanding industrial applications.

Hydrogenated Nitrile (HNBR)

Hydrogenated nitrile rubber (HNBR) is an advanced variant of NBR, engineered for enhanced performance in harsh environments. While standard nitrile rubbers are less resistant to chemicals and oils, HNBR compounds excel, particularly at higher temperatures. HNBR demonstrates exceptional resistance to fuels, lubricants, numerous chemicals, ozone, and steam, making it a preferred choice for applications in the automotive, oil & gas, and power generation sectors. This material also boasts superior elongation, abrasion resistance, tear strength, and tensile strength. HNBR is commonly utilized in automotive components such as hoses, static seals, and timing belts, as well as in power transformers and corrosion-resistant coatings for electrical devices. For those seeking reliability in chemically aggressive or temperature-extreme environments, HNBR rubber sheets are a leading solution.

EPDM Rubber Sheet

EPDM (Ethylene Propylene Diene Monomer) rubber sheets are elastomers with a wide range of industrial and commercial uses, thanks to their unique polymethylene-type saturation chains. EPDM is especially valued for its outstanding resistance to weathering, ozone, UV radiation, and aging. It remains flexible even at low temperatures and resists water, steam, and some chemicals. These properties make EPDM rubber sheets ideal for roofing membranes, outdoor gaskets, seals in windows and doors, pond liners, and automotive weather-stripping. If you're seeking a rubber sheet that offers long-term durability in outdoor or harsh environmental conditions, EPDM is an excellent choice.

Silicone Rubber Sheets

Silicone rubber sheeting is an extremely flexible and temperature-resistant engineering material, widely adopted by the pharmaceutical, food processing, and electronics industries. Silicone rubber sheets resist chemicals, extreme temperatures (ranging from -94°F to 482°F, or -70°C to 250°C), and aging caused by weather. They have low permeability to gases and liquids, making them suitable for hygienic and clean-room environments. Due to its exceptional resistance to UV light, ozone, and weathering, silicone rubber is well-suited for outdoor applications and demanding environments. Commercial and industrial sectors utilize silicone rubber sheets in medical device manufacturing, food-grade sealing, insulation, and high-temperature gaskets. Are you looking for a rubber sheet for high-temperature or sanitary applications? Silicone rubber sheets deliver superior performance in these scenarios.

Viton Sheets (Fluoroelastomer Rubber Sheets)

Viton sheets are manufactured from fluoroelastomer materials, specifically designed for extreme chemical and temperature resistance. This remarkable synthetic rubber and fluoropolymer elastomer offers temperature stability from -4°F to 401°F (-20°C to 205°C), making it the go-to choice for industries requiring long-term durability in the presence of aggressive chemicals, fuels, or solvents. Viton rubber sheets are highly resistant to oils, acids, hydrocarbons, and a wide spectrum of chemicals, which is why they are extensively used in the aerospace, automotive, chemical processing, and petrochemical industries. If your application demands high-performance sealing or gasketing in environments exposed to corrosive substances and elevated temperatures, Viton rubber sheets are among the best options available.

Applications of Rubber Sheets

- Sealing and Gasketing: Rubber sheets are widely used to manufacture seals, o-rings, gaskets, and washers for a variety of industrial, automotive, and plumbing applications. Their flexibility and resistance to oils, chemicals, and water ensure leak-proof performance in pipelines, pumps, and machinery.

- Insulation and Protection: In electrical and electronic industries, rubber sheets serve as insulating mats for high-voltage environments, preventing electrical shocks and providing safety for workers. They are also used in speaker cone surrounds, solar panel heat collectors, and electronic component protection.

- Vibration and Shock Absorption: Due to their excellent vibration-damping properties, rubber sheets are utilized as anti-vibration pads, shock absorbers, and mountings in heavy machinery, automotive engines, and industrial equipment. This helps prolong machine life and minimize noise.

- Waterproofing and Weatherproofing: Industrial production often employs rubber sheets as waterproof covers or seals for mechanical purposes. Common uses include door and joint seals in the automotive sector, roofing membranes, and pond liners to prevent leaks and water ingress.

- Flooring and Surface Protection: Rubber sheets are a popular choice for flooring in gyms, factories, playgrounds, garages, and automotive interiors. Their non-slip surface, resilience, and resistance to wear make them ideal for high-traffic areas. Explore our range of rubber flooring solutions for more details.

- Personal Protective Equipment (PPE): Rubber sheets are used to produce gloves, boots, aprons, and other PPE for workers in chemical, food processing, and healthcare environments due to their excellent barrier properties.

- Food and Beverage Industry: In food processing facilities, food-grade rubber sheets are used as workstation pads, conveyor belts, and gaskets for hygienic sealing. Their resistance to oils and ease of cleaning make them suitable for sanitary applications.

- Automotive and Aerospace: Rubber sheets play a crucial role in manufacturing tires, belts, hoses, and vibration-dampening components for vehicles and aircraft. Their ability to withstand high mechanical stress and harsh environmental conditions is vital for safety and performance.

- Gardening and Home Use: Rubber sheets and rolls are commonly found in garden hoses, pond liners, anti-slip mats, and appliance pads. Their versatility makes them suitable for a wide range of residential and commercial uses.

- Industrial Manufacturing: Rubber sheets are used in conveyor belts, machinery pads, equipment enclosure linings, and as protective barriers against chemicals, abrasion, and impact.

- Chemical and Petrochemical Processing: These sectors demand rubber sheeting that can withstand aggressive chemicals, acids, and solvents, which is why Viton and EPDM sheets are often chosen for lining tanks, pipes, and reactors.

Wondering which rubber sheet is best for your specific application? Contact our experts for personalized recommendations or request technical datasheets for comparison.

Benefits of Rubber Sheets

Safety of the Work Surface

Rubber sheeting provides practical protection for work surfaces, acting as an effective cushion or bump stop. Its elastic nature helps shield machinery surfaces and industrial floors from damage due to impacts, abrasion, or dropped tools. This not only extends the lifespan of equipment but also reduces maintenance costs, making rubber sheets a valuable investment for manufacturing, automotive, and laboratory environments.

Personnel Safety

Safety is a key advantage of rubber sheets, as they offer non-slip and insulating properties—making them suitable for flooring in public spaces, workstations, and high-voltage environments. Industrial-grade rubber sheeting helps prevent slips, falls, and electrical accidents, enhancing safety for both users and personnel. For industries with strict safety standards, such as power plants and chemical processing facilities, rubber insulation mats are essential.

Protection of Machines

Rubber sheets act as shock absorbers, safeguarding sensitive machinery from vibrations, shocks, and mechanical stress. This is particularly important for equipment with moving parts or delicate calibration, as consistent vibrations can lead to premature wear, misalignment, or failure. Rubber sheet gaskets also prevent the leakage of liquids and gases, ensuring process integrity in pipelines, HVAC systems, and pressure vessels. Investing in high-quality rubber sheet gaskets can significantly reduce downtime and improve operational efficiency.

Anti-Vibration Properties

Rubber has a built-in ability to dampen vibrations caused by machines. In industrial settings, excessive vibrations may eventually cause wear on devices and disrupt workflow. Rubber anti-vibration pads and mounts absorb these forces, reducing noise and prolonging machine lifespan. Are you looking for ways to minimize noise and vibration in your facility? Explore our anti-vibration rubber products for tailored solutions.

Electrical and Mechanical Resistance

Rubber is electrically non-conductive, making it ideal for insulation in electrical and electronic applications. It resists rust, corrosion, and discoloration, even in challenging industrial environments. This property is especially relevant in power distribution, switchgear rooms, and manufacturing lines where worker safety and equipment protection are paramount.

Versatility and Customization

Rubber sheets are highly versatile and can be custom-cut or fabricated into a wide range of products, such as pads, washers, gaskets, strips, and mats. Available in different thicknesses, durometers (hardness), and colors, rubber sheeting can be tailored to meet the unique requirements of virtually any industry. Whether you need FDA-approved, flame-retardant, oil-resistant, or high-temperature rubber sheets, there is a material to match your specifications. Need a custom rubber solution? Request a quote for precision-cut rubber sheets to fit your project.

Wide Availability and Cost-Effectiveness

Rubber sheets are readily available in various grades, sizes, and formulations, making them a convenient and economical choice for both small businesses and large-scale industries. The competitive pricing and long service life of rubber sheeting contribute to lower total cost of ownership compared to alternative materials. Whether you are seeking bulk rolls or cut-to-size sheets, most rubber sheet suppliers offer fast turnaround and delivery options.

Environmental Benefits

Many rubber sheets, especially those made from recycled or natural rubber, offer environmentally friendly benefits. Using recycled rubber in flooring, playgrounds, or industrial mats helps reduce landfill waste and supports sustainability goals. Moreover, the durability and long service life of quality rubber sheets minimize the need for frequent replacements, reducing environmental impact over time.

Decision Factors: How to Choose the Right Rubber Sheet

Consider Application Requirements

Start by identifying the specific requirements of your application: Will the rubber sheet be exposed to oils, chemicals, extreme temperatures, or UV radiation? Is mechanical strength, flexibility, or electrical insulation a priority? The answers will help determine whether you need NBR, EPDM, silicone, Viton, or natural rubber sheets.

Thickness and Hardness

The thickness and durometer (hardness) of a rubber sheet affect its resilience, flexibility, and load-bearing capacity. Thicker sheets provide better cushioning and impact resistance, while harder sheets are suited for heavy-duty sealing or abrasion-prone environments. Not sure which thickness is right for you? Ask our product specialists for guidance.

Regulatory and Safety Standards

For applications in food, healthcare, or sensitive industrial environments, ensure your rubber sheets meet relevant regulatory standards, such as FDA, REACH, or RoHS compliance. Food-grade and medical-grade rubber sheets are manufactured under strict quality controls for safety and hygiene.

Customization and Fabrication

Many suppliers offer custom rubber sheet fabrication, including die-cutting, waterjet cutting, adhesive backing, and vulcanization. Customization ensures a precise fit and optimal performance for your unique application. Interested in custom sizes or shapes? Get a quote on custom fabrication.

Supplier Reliability and Service

When sourcing rubber sheets, partnering with a reputable supplier ensures consistent quality, technical support, and access to a broad product range. Compare suppliers based on their experience, inventory, certifications, and ability to deliver tailored solutions for your industry.

Choosing the Proper Rubber Sheet Supplier

To ensure the most beneficial outcome when purchasing rubber sheets from a supplier, it is important to compare at least 4 to 5 companies using our curated list of rubber sheet suppliers. Each supplier has a business profile page highlighting their areas of expertise, certifications, and production capabilities, along with a direct contact form for more information or to request a quote. Review each supplier’s website using our proprietary website previewer to get an overview of their product range and specialization. Our simple RFQ (Request for Quote) form allows you to contact multiple rubber sheet suppliers simultaneously, streamlining your procurement process and helping you secure the best pricing and lead times.

Are you searching for the best deals on high-quality rubber sheets for industrial, commercial, or specialized applications? Browse our supplier directory or submit a quote request to connect with trusted rubber sheet manufacturers and distributors who can fulfill your needs quickly and efficiently.

For more information on specific types of rubber sheets, technical datasheets, or application advice, visit our rubber sheet resources page or reach out to our expert team for personalized recommendations. Whether you’re sourcing for automotive, food processing, chemical, construction, or general industrial use, we are here to help you find the right material and supplier for your project.

Frequently Asked Questions About Rubber Sheets

What is the difference between natural and synthetic rubber sheets?

Natural rubber sheets are derived from latex harvested from rubber trees, offering excellent elasticity, tensile strength, and resilience. Synthetic rubber sheets, such as NBR, EPDM, or silicone, are engineered for specific properties, including oil, chemical, or temperature resistance. The choice depends on application requirements and environmental conditions.

How do I select the correct thickness and hardness for my rubber sheet?

Consider the application’s mechanical demands: Thicker sheets are better for cushioning or vibration damping, while thinner sheets provide flexibility for gaskets and seals. Hardness (durometer) impacts load-bearing capacity and abrasion resistance. Consult our rubber sheet selection guide for detailed recommendations.

Are rubber sheets suitable for outdoor use?

Yes, certain rubber materials like EPDM and silicone are specifically formulated for outdoor use, offering superior UV, ozone, and weather resistance. Always choose a material rated for environmental exposure to ensure longevity.

Can I get custom-cut rubber sheets for my project?

Absolutely. Most reputable suppliers offer custom fabrication services, including die-cutting, waterjet cutting, and adhesive backing. Submit a custom quote request for your specific dimensions and requirements.

Where can I buy high-quality rubber sheets online?

Our supplier directory features vetted manufacturers and distributors offering a wide selection of rubber sheets for industrial, commercial, and consumer applications. Use our quote request form to connect with suppliers that meet your needs.

Contact Us

Looking for expert assistance in choosing the right rubber sheet material, thickness, or supplier? Our knowledgeable team is ready to help you with technical support, material selection, and sourcing. Contact us today for fast, friendly, and professional service.

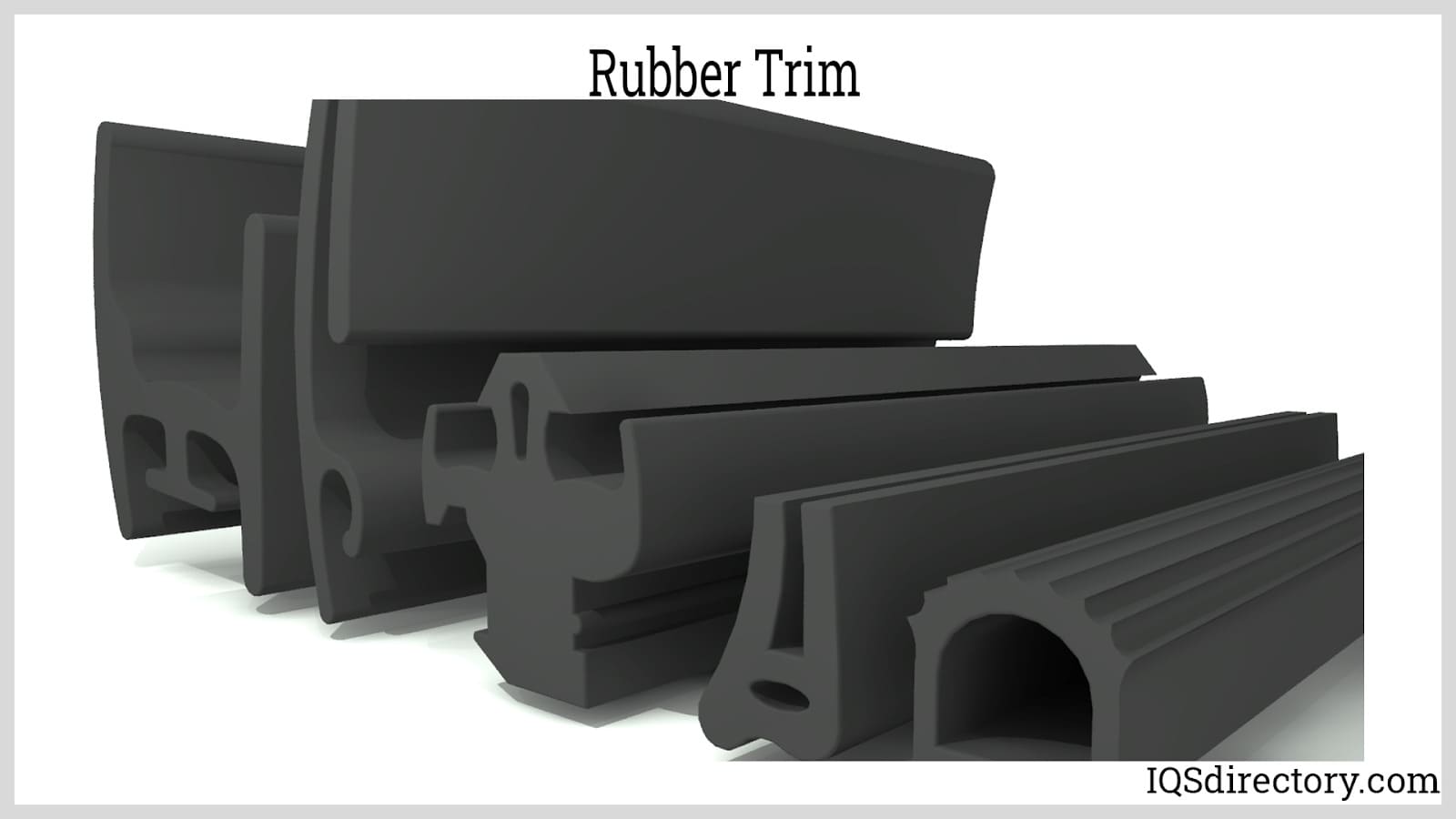

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services