Rubber seals are used in a wide variety of industrial and consumer applications. Read More…

Aero Rubber Co. offers exceptional quality and competitive pricing on all of our extruded rubber products. Aero Rubber Co. uses high quality rubber compounds such as, Neoprene, Viton, Silicone, EPDM, Polyurethane, Natural Rubber, and Thermoplastic Rubber.

Since 1976, Lakeview Industries has been globally known for manufacturing rubber extrusions. Our die cut equipment and fabricated rubber products such as rubber grommets and rubber bumpers provide the environmental sealing and noise control industries with reliable molded rubber products. We do both standard and custom profiles to help meet your rubber requirements.

GSH Industries supplies rubber extrusions to a range of industries. We offer rubber in materials such as Neoprene, Viton®, Nitrile, Silicone & more. We have tooling ability to create intricate profiles ensuring rubber goods are of the highest quality.

At American Rubber Products, we take pride in our expertise and commitment to delivering top-notch rubber extrusions. With decades of collective experience, we specialize in providing high-quality solutions tailored to meet the unique needs of our diverse clientele. Join us on the journey of excellence, where passion and proficiency converge to create unparalleled rubber extrusion solutions that...

We got our beginning in 1954 and ever since then we have been manufacturing custom rubber extrusion solutions for customers around the world! We are a family and employee owned business dedicated to ensuring that our customers are receiving customer care that cannot be matched by the competition! Visit our website today to learn more about what we may be able to do for you!

More Extruded Rubber Seals Manufacturers

Many kinds of manufacturing machinery make use of extruded rubber seals, particularly in manufacturing processes that involve fluids or pressurization. Machinery that is sensitive to environmental conditions or dust accumulation may also be shielded using some variety of rubber sealant, though some extruded rubber compositions can be damaged if exposed to certain chemicals or extreme temperatures. Rubber seals are an essential component in aerospace and marine applications where atmospheric stabilization or pressurization is necessary.

In consumer contexts, rubber seals can be found in swimming pool pump systems, garden hoses, bathrooms, kitchens, as insulation and weatherstripping and in many other applications. A rubber seal can be a film, gel, solid, putty or strip and will adhere to ceramics, glass, concrete, bricks, paper, other rubber materials, leather, textiles, metal, plastic, wood and many porous surfaces and composite materials.

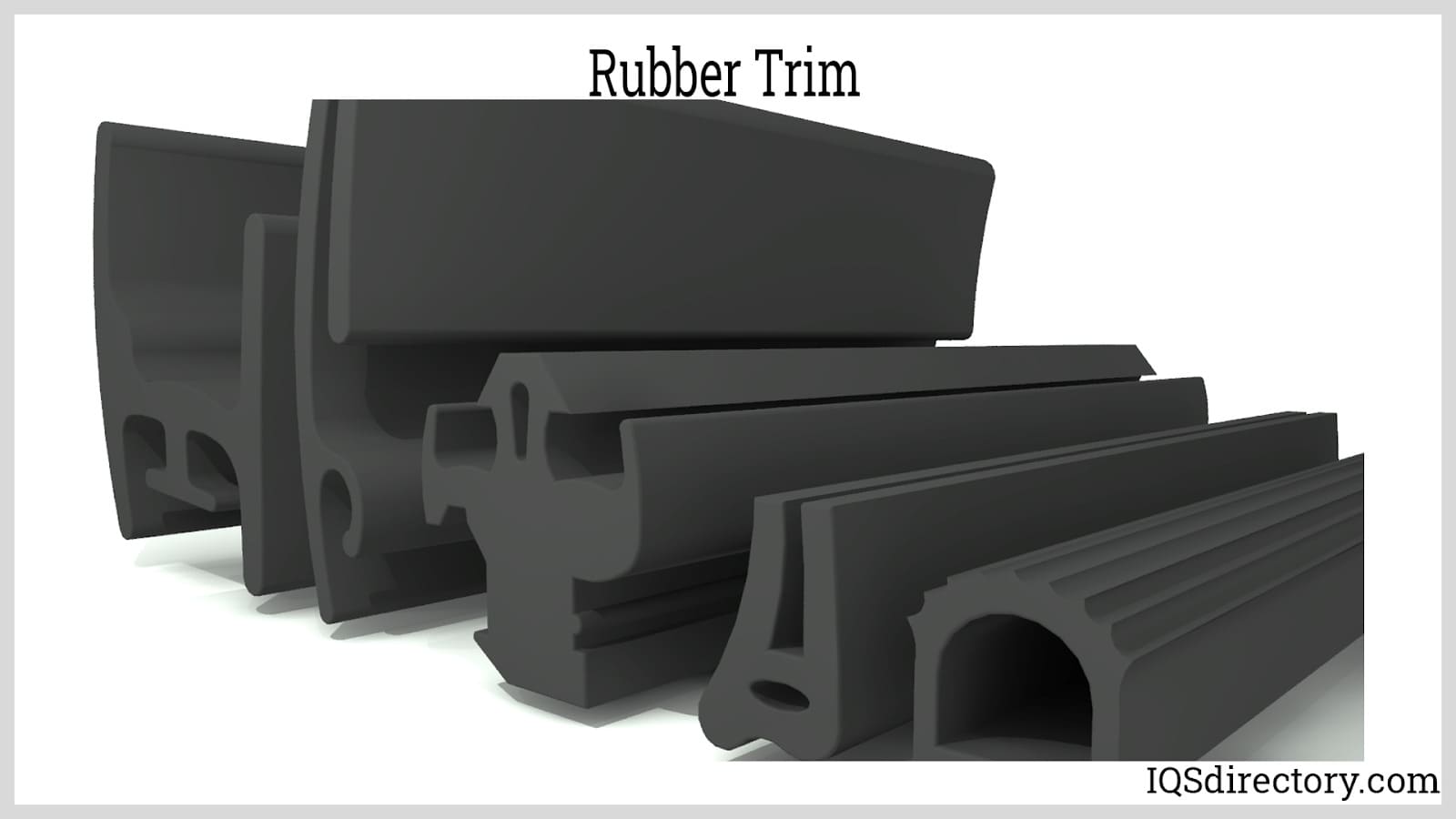

Rubber is an elastometer and can be created from collecting natural materials and from artificial synthesis. In order to become usable, it must be processed. Like all rubber products, rubber seals are processed in some way. In some applications, as is the case with rubber trim, a machine or series of machines called rubber extruders will process the raw material so that it takes on a more appropriate shape or qualities for its application.

Extruded Rubber is more useful as a temporary sealant as it can be placed and removed without damaging the sealant or the surface where it is applied. Examples of extruded rubber seals include weatherizing strips as well as plugs and stoppers. Non-extruded rubber sealants are used in contexts when a seal needs to be tailored to fit into, around or between surfaces. Such sealants are often manufactured, distributed and applied by the end-user as liquids or gels, and then they harden with time. Examples of applications for these varieties of sealant include caulking and waterproofing.

Neither extruded nor non-extruded rubber seals are designed to serve as permanent sealants. Re-application of non-extruded rubber seals is required at intervals as they are degraded by atmospheric conditions and as time passes. Extruded rubber seals, which are more frequently used in industrial settings, are subject to frequent or constant wear and also need to be replaced regularly. However, rubber seals are often an inexpensive sealant solution, and the cost of their occasional replacement is often much less than the cost of damages to the things they protect.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services