Rubber extrusion is the process of shaping rubber materials into a certain shape. Manufacturers utilize a rubber extruder machine to create this form. Read More…

Aero Rubber Co. offers exceptional quality and competitive pricing on all of our extruded rubber products. Aero Rubber Co. uses high quality rubber compounds such as, Neoprene, Viton, Silicone, EPDM, Polyurethane, Natural Rubber, and Thermoplastic Rubber.

Since 1976, Lakeview Industries has been globally known for manufacturing rubber extrusions. Our die cut equipment and fabricated rubber products such as rubber grommets and rubber bumpers provide the environmental sealing and noise control industries with reliable molded rubber products. We do both standard and custom profiles to help meet your rubber requirements.

GSH Industries supplies rubber extrusions to a range of industries. We offer rubber in materials such as Neoprene, Viton®, Nitrile, Silicone & more. We have tooling ability to create intricate profiles ensuring rubber goods are of the highest quality.

At American Rubber Products, we take pride in our expertise and commitment to delivering top-notch rubber extrusions. With decades of collective experience, we specialize in providing high-quality solutions tailored to meet the unique needs of our diverse clientele. Join us on the journey of excellence, where passion and proficiency converge to create unparalleled rubber extrusion solutions that...

We got our beginning in 1954 and ever since then we have been manufacturing custom rubber extrusion solutions for customers around the world! We are a family and employee owned business dedicated to ensuring that our customers are receiving customer care that cannot be matched by the competition! Visit our website today to learn more about what we may be able to do for you!

More Extruded Rubber Manufacturers

What is Extruded Rubber?

A heated shearing screw conveyor and a die are the two basic components of a rubber extruder. Under the pressure of an extruder, extruded pieces are driven into a die with the requisite cross-section.

Soft, unvulcanized rubber compounds are commonly fed into the extruder to make these pieces. The rubber remains soft and malleable as a result of the extrusion process. The resulting extruded items in this situation will often need to be vulcanized, or hardened, before they can be used.

Rubber Extrusion Process

To begin the rubber extrusion process, a rubber compound is put into an extruder. Next, the material goes into a feed hopper, which collects and feeds it into the flutes of a rotating screw.

The rubber will be carried forward into the die by the screw, with pressure and temperature increasing as the material gets closer to the die.

When the material reaches the die, the built-up pressure drives it through the apertures, causing it to expand to different degrees depending on the material compound and hardness. Due to this expansion tendency, many extruded items require plus or minus tolerances on their cross-sections.

Depending on the rubber compound employed, the extruded rubber will expand or shrink in cross-sections and length during vulcanization.

After vulcanization, a length of rubber extrusion will shrink in size more in the middle of the length than at the ends.

Die For Rubber Extrusion

An extrusion die is a precise and particular instrument created by cutting a hole in a steel blank. The opening will be shaped to fit the desired finished rubber cross-section for an extruded item.

Once in place, the rubber material will be driven through the die by the pressure generated by the extruder's revolving screw. Many rubber compounds swell as they pass through the extrusion die, causing them to expand in size.

As a result, each die is customized for each part and material to ensure that the finished extruded rubber part meets all tolerances.

Lathe Cut Rubber

Extruding a tube of rubber, cutting it to a specific length, sliding it onto a mandrel, curing the material, grinding the OD, and finally cutting the finished item to length using a lathe are all steps in the lathe cutting process.

Washers and gaskets with high precision tolerances are good candidates for this technique. Square-cut edged components are optimal for this operation; however, in some circumstances, a beveled edge can be added. The majority of today's elastomeric materials can be made utilizing the lathe cutting method.

This method is commonly used to make everything from small washers for garden hoses to big gaskets for pails or drum lids. In general, this production process is best suited for high-volume applications.

Mandrel Formed Tubing

Mandrel forming is a labor-intensive and one-of-a-kind procedure. The material is first extruded to a defined outer and inside diameter before being cut to a specific length. The tubes are then inserted or pressed onto a mandrel in the shape of the finished item via a process called "sticking."

A cart with a rack of mandrels is used for high-volume applications. The cart is then transferred into the autoclave for curing once the tubes have been "stuck." The components are removed from the mandrels after curing.

Most of the time, the parts are moved to a sort of washing machine to remove any release agents or other materials utilized throughout the procedure. The ends of the components are chopped to length with a chop saw after they have been washed.

Components where kinking in a straight tube could occur if bent are common uses for mandrel-produced parts. This procedure involves both simple 90-degree bends and more sophisticated multiple bends.

Applications of Extruded Rubber

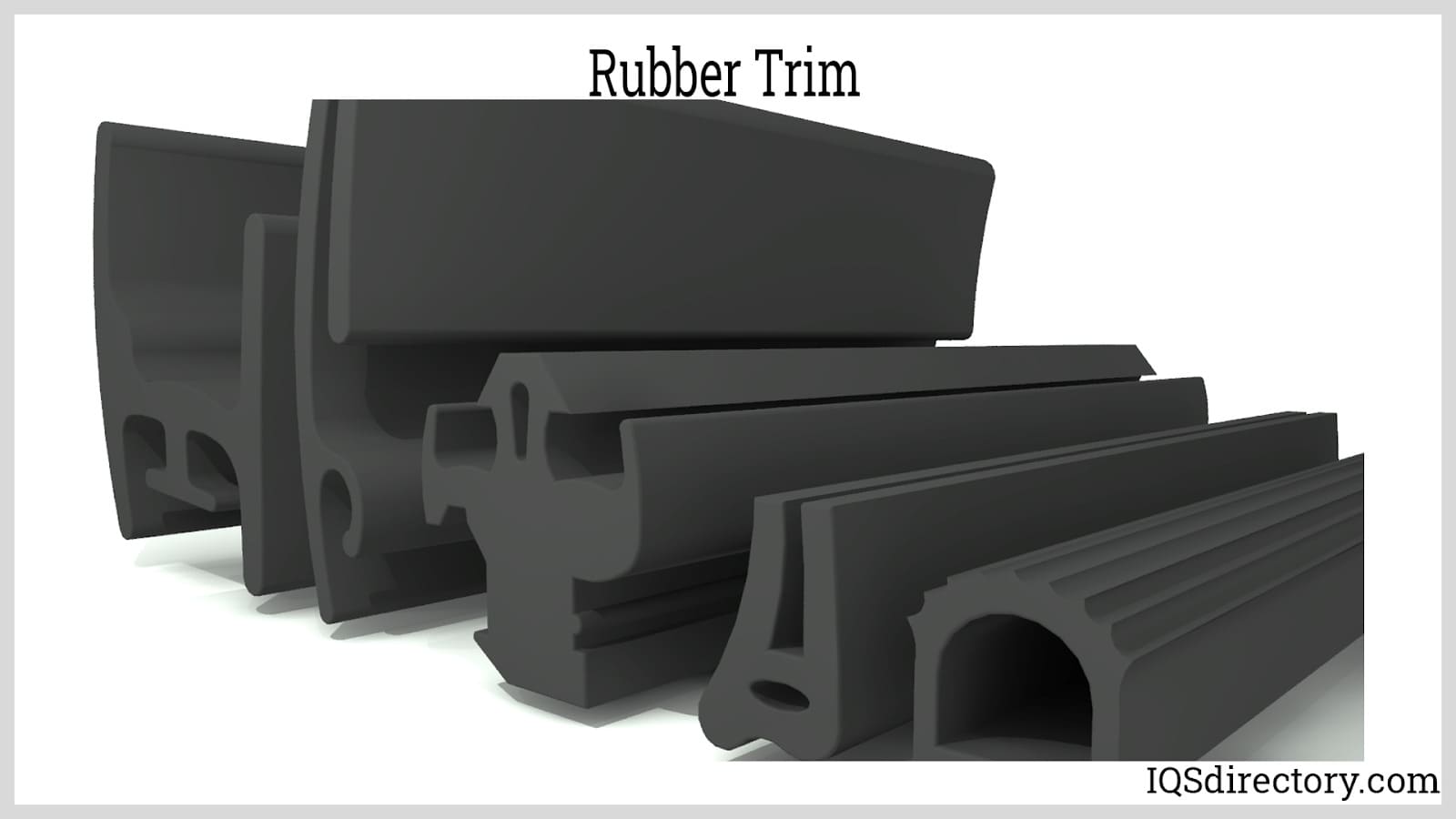

Custom rubber extrusions can be cut from extruded rubber in various lengths, forms, and rubber compounds to fulfill a variety of temperature, weather, and technical requirements.

EPDM or neoprene, for example, can be extruded like dense rubber or sponge rubber. Extruded rubber items include the following:

- Connectors

- Tubing

- Hoses with mandrels

- Seals for doors, cabinets, and windows

- Vibration dampeners

- Gaskets

- Spliced gaskets

- Window sealing for public transportation

- Square tubes for pressure switches

Advantages of Rubber Extrusion

The rubber extrusion technique has numerous advantages, including:

- Various available forms

- Effective and cost-effective

- Flexible, light products

- Minimized waste

Choosing the Right Extruded Rubber Supplier

To make sure you have the most positive outcome when purchasing extruded rubber from an extruded rubber supplier, it is important to compare at least 4 suppliers using our extruded rubber directory. Each extruded rubber supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier or request a quote. Review each extruded rubber business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple extruded rubber businesses with the same message.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services