Rubber goods are processed by machines called rubber extruders. Extrusion is the process of heating, pressing, cooling, and forcing raw material through a die to shape it into a new shape. First, tools called dies are created specifically to mold raw materials into new shapes. After that, the substance is thoroughly cooled and hardened. Read More…

Aero Rubber Co. offers exceptional quality and competitive pricing on all of our extruded rubber products. Aero Rubber Co. uses high quality rubber compounds such as, Neoprene, Viton, Silicone, EPDM, Polyurethane, Natural Rubber, and Thermoplastic Rubber.

Since 1976, Lakeview Industries has been globally known for manufacturing rubber extrusions. Our die cut equipment and fabricated rubber products such as rubber grommets and rubber bumpers provide the environmental sealing and noise control industries with reliable molded rubber products. We do both standard and custom profiles to help meet your rubber requirements.

GSH Industries supplies rubber extrusions to a range of industries. We offer rubber in materials such as Neoprene, Viton®, Nitrile, Silicone & more. We have tooling ability to create intricate profiles ensuring rubber goods are of the highest quality.

At American Rubber Products, we take pride in our expertise and commitment to delivering top-notch rubber extrusions. With decades of collective experience, we specialize in providing high-quality solutions tailored to meet the unique needs of our diverse clientele. Join us on the journey of excellence, where passion and proficiency converge to create unparalleled rubber extrusion solutions that...

We got our beginning in 1954 and ever since then we have been manufacturing custom rubber extrusion solutions for customers around the world! We are a family and employee owned business dedicated to ensuring that our customers are receiving customer care that cannot be matched by the competition! Visit our website today to learn more about what we may be able to do for you!

More Rubber Extruder Manufacturers

Rubber Extrusion Process

A rubber compound is put into an extruder to begin the rubber extrusion process. The substance is put into a feed hopper, which transfers the substance into different flutes of a rotating screw. The rubber will start to go into the die as the screw turns, and as it approaches the die itself, pressure and temperature will rise.

The pressure that builds up as the material enters the die forces it through the apertures, where it will subsequently expand to varying degrees depending on the composition and hardness of the material. Due to this tendency to swell, many extruded items need plus or minus tolerances on their cross sections. Depending on the rubber compound employed, the extruded rubber will expand or shrink in its cross-section and length during vulcanization. A rubber extrusion’s length will often shrink in size more in the middle than the ends after vulcanization.

Rubber Extruder Applications

Both natural and synthetic rubber can be extruded, as can the majority of industrially relevant raw materials that can be liquefied. Weatherstripping, trim items, little grommets, and big bumpers are just a few examples of which form industrial products of rubber extrusions can take. A rubber extruder used by a business that provides services to the heating and cooling sector will be set differently from equipment that provides services to the automobile industry since the demand for rubber extrusions varies from industry to industry.

Products from Rubber Extruders

- Rubber Bushings: Extruded rubber bushings act as shock absorbers in moving machinery. They keep moving parts separate from one another and prevent vibration and noise from resonating throughout a system. They are commonly seen in automobile systems, particularly in suspension components. Most rubber bushings have hollow cylinder shapes that can be easily produced using the extrusion process. The dimensions of the part or shaft it fits into define its length. Some rubber bushings are only used in their unprocessed state, whereas others are enclosed and connected by metal sleeves or casings.

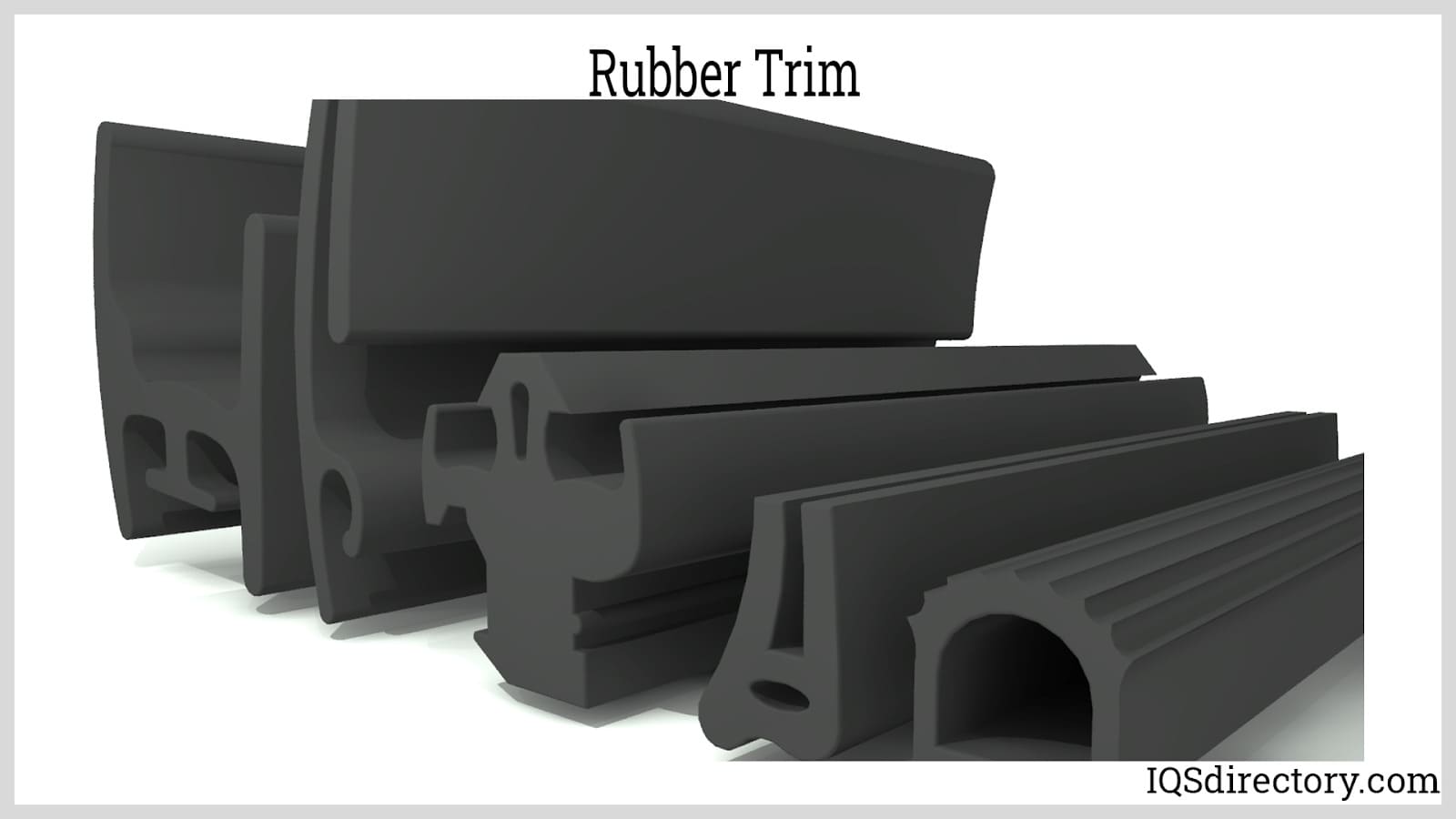

- Rubber Trims: Made from extruded rubber, rubber trims are used to cushion the edges and surfaces of rigid items from shocks. Panels, windows, doors, removable coverings, and hatches are examples of these items. In addition to offering impact protection, they seal the mating parts against air and water leaks. There are countless rubber trim profiles available, many of which are developed specifically for a particular use. A U-channel is one of the most widely used shapes for rubber trim. Fasteners and adhesives are used to secure the rigid part's edge in the channel after it has been introduced.

- Rubber Bumpers: Rubber bumpers use the material's shock-absorbing properties, similar to rubber trim and bushings. In addition to this quality, the materials used in the compounding process to create rubber bumpers also include a small amount of abrasion resistance to increase their durability. They are frequently employed in road safety equipment, jetty, boat fenders, docks, and loading bays for trailer trucks. Rubber bumper cross-sections often have a D-shaped shape. As a result, the bumper can have one side fastened to a wall while the other side takes the impact. The impact-absorbing side's rounded design shields the crashing vehicle from harm.

- Additional Products: Regardless of the type of material used, extrusion is frequently used to create rubber tubes, hoses, and pipes. Hydraulic and pneumatic controls for industrial equipment frequently employ rubber extrusions. Rubber extrusions are widely used in the production equipment of food and drugs. Thanks to its exceptional flexibility, rubber can be bent into any shape without harm. These qualities make these goods appealing for joining various machinery for moving fluids such as compressed air, oil, water, and chemicals.

Finishing Processes for Rubber Extrusions

Punching

For extruded items that become bumpers, fenders, or hatch seals, holes or slots must typically be punched into the rubber. These come in various sizes and forms and can be used on parts for alignment, venting, and fastening.

Cutting

Not all extrusions are the correct length after being vulcanized. Rubber extrusions must then be cut to the desired length. With an offline cut, it is possible to produce angles or miters with tighter tolerances. Fly cutters and guillotines can quickly cut smoother or shorter lengths of extrusion.

Printing

Printing numbers inline after vulcanization provides an alternative for traceability. The parts can be printed with identifiers like websites, phone numbers, times and dates, lot or batch numbers, patent identification numbers, and, in some situations, barcodes.

Drilling

Drilling is similar to punching; following vulcanization, extrusions can have holes and slots drilled into them. Compared to punching, this technique can handle thicker and harder materials.

Forming the Corners

It is feasible to mold two extrusions together after the extrusion process. This ability makes it possible to make frames and corners for window and container door seals.

Riveting and Welding

Specific extrusions can be welded or riveted to other materials to create specialized goods like the flexible rollaway bank ladder.

Choosing the Correct Rubber Extruder Manufacturer

To make sure you have the most productive outcome when purchasing rubber extruders from a rubber extruder manufacturer, it is important to compare at least 4 manufacturers using our rubber extruder directory. Each rubber extruder manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each rubber extruder business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple rubber extruder manufacturers with the same quote.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services