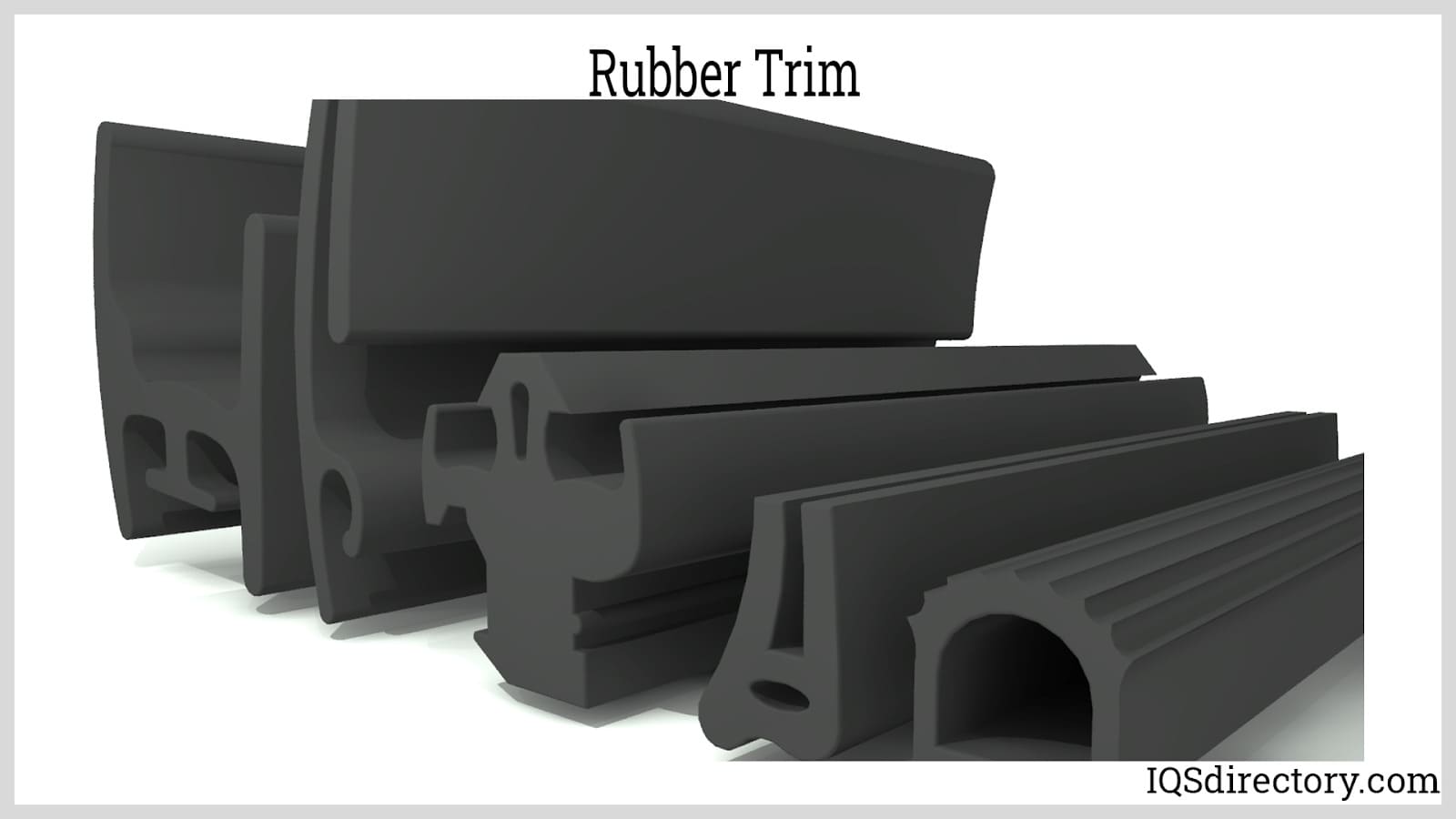

Rubber edge trim covers exposed metal edges and seals gaps. Rubber trims also function as rubber gaskets or O-rings, sealing the edges of mated parts. Rubber trims are produced using various profiles and molded for a particular use. The profiles are designed, machined onto a die, and then mounted on an extrusion machine to produce the rubber product.Read More…

Aero Rubber Co. offers exceptional quality and competitive pricing on all of our extruded rubber products. Aero Rubber Co. uses high quality rubber compounds such as, Neoprene, Viton, Silicone, EPDM, Polyurethane, Natural Rubber, and Thermoplastic Rubber.

Since 1976, Lakeview Industries has been globally known for manufacturing rubber extrusions. Our die cut equipment and fabricated rubber products such as rubber grommets and rubber bumpers provide the environmental sealing and noise control industries with reliable molded rubber products. We do both standard and custom profiles to help meet your rubber requirements.

GSH Industries supplies rubber extrusions to a range of industries. We offer rubber in materials such as Neoprene, Viton®, Nitrile, Silicone & more. We have tooling ability to create intricate profiles ensuring rubber goods are of the highest quality.

At American Rubber Products, we take pride in our expertise and commitment to delivering top-notch rubber extrusions. With decades of collective experience, we specialize in providing high-quality solutions tailored to meet the unique needs of our diverse clientele. Join us on the journey of excellence, where passion and proficiency converge to create unparalleled rubber extrusion solutions that...

We got our beginning in 1954 and ever since then we have been manufacturing custom rubber extrusion solutions for customers around the world! We are a family and employee owned business dedicated to ensuring that our customers are receiving customer care that cannot be matched by the competition! Visit our website today to learn more about what we may be able to do for you!

More Rubber Trim Manufacturers

The most common edge protection is a U-channel. A metal fastener or an adhesive is used to secure the edge of the part or substrate into the channel's open side. Some designs can secure the rubber trim in place without needing a permanent attachment by having protrusions or tongues along the interior of the channel.

Types of Rubber Trim

EPDM Edge Trim

EPDM edge trim is a synthetic rubber that withstands extreme temperatures and resists moisture. Products made of EPDM rubber are resistant to alkalis, acids, water, steam, and oxygenated solvents. Manufacturers should consider EDPM edge trim for machinery, outdoor use, and car door edges.

Silicone Edge Trim

Silicone edge trim is used in sanitary or hygienic products. Silicone remains stable over a wide range of temperatures. Therefore, silicone edge trim is ideal for medical and food processing products. When choosing a silicone edge trim, remember there are multiple silicones with differing properties. For example, some silicones cannot be recycled.

Chloroprene (Neoprene) Rubber (CR)

Neoprene is a chloroprene polymer created using emulsion polymerization. Neoprene can resist oxidation, ozone, and oil. However, neoprene operates poorly at low temperatures and is more expensive than natural rubber.

Polyisoprene Rubber (IR)

Polyisoprene rubber is made from isoprene monomers. Polyisoprene rubber is similar to natural rubbers found in plants. However, IR is chemically purer than natural rubber. IR’s may be more useful to manufacturers than natural rubber because it is created in a controlled setting.

TPE Edge Trim

Thermoplastic elastomers (TPE) are rubber-like materials that combine thermoplastic strength with the flexibility of thermoset rubbers. TPE costs more than other rubbers.

TPE rubber edge trim is perfect for window trim since it's lightweight, comes in various colors, and is simple to install. In the Elasto Proxy inventory, many different TPE products are available. Although TPE has several benefits, purchasers and designers should be aware of how poorly it recovers from heat and compression.

Applications of Rubber Trim

Covering Metal Edges

Rubber trim can be applied to sheet metal to protect the edges of the material.

Vehicle Doors

Rubber trim covers most of the metallic parts in car doors and handles. This protects the users from any risks of electrocution and an aesthetic finish.

Transportation and Shipment

Rubber trim can be used to protect equipment during its shipment by absorbing shock.

Choosing the Right Rubber Trim Manufacturer

To make sure you have the most productive outcome when purchasing rubber trim from a rubber trim manufacturer, it is important to compare at least 5 manufacturers using our rubber trim directory. Each rubber trim manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each rubber trim company website using our patented website previewer to get an idea of what each company specializes in and then use our simple RFQ form to contact multiple rubber trim companies with the same message.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services